Mobile cleaning > Why we?

GUARANTEED QUALITY

Why more than 400 printing houses in Europe have chosen our cleaning procedure?

Our team cleans aniloxes with laser since 2010 and have served more than 600 clients. This experience allows us to say that no existing cleaning method apart from laser cleaning enables to fully remove residue from the cells of the anilox roll.

LaserEcoClean enables you to clean your anilox rolls as often as your production needs are without any negative effects to the surface of the anilox roll.

Every producer of anilox cleaning equipment (chemistry, soda or ultrasonic) claims to have the best method and says with his method the anilox rolls are 100% clean.

However only LaserEcoClean technology gives you a guarantee for the homogeneous and full residues removal from the cells of the anilox roll. The cleaning process is fully automated. Your personnel do not require any special competences, they just have to put the anilox roll into the machine and bring the number of the anilox roll in.

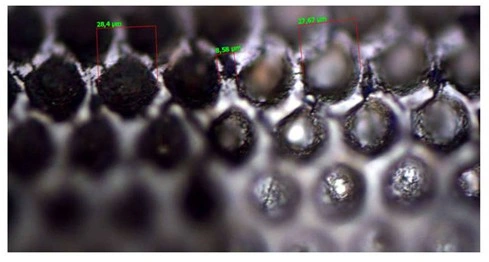

All mentioned above can be proved with facts. For each cleaned anilox roll you receive a pdf cleaning protocol with microscopic photos of the cells. We also are glad to measure for you the line screen and the ink transmission of your roll upon a request.

The cleaning result of a anilox rolls with line screen 400l/cm

Your aniloxes can be also restored after the fire, long storing and

using waterbased, white and titanous inks.