Mobile cleaning > Why we? > Comparison LaserEcoClean

COMPARISON OF TWO DIFFERENT TYPES OF CLEANING: CHEMICAL (RECYL COBRA) AND LASER (LASERECOCLEAN)

Bellow you can see the cleaning results of the anilox rolls with line screen 340 lpi and volume of 4.9 vol.

Comparison was made in the following way: 1) firstly the roll was cleaned with Recyl Cobra. Next day the half of the roll was cleaned with laser. Optical density was measured with a densitometer, print were made with spot cyan ink. On the printing sheet cyan spots were measured 6-7 times in different places across whole print field. The measurements were made before the cleaning with cobra and after each cleaning.

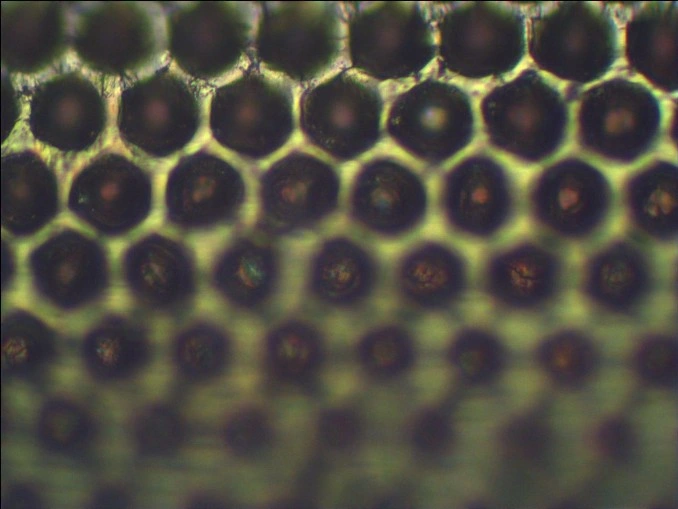

01.

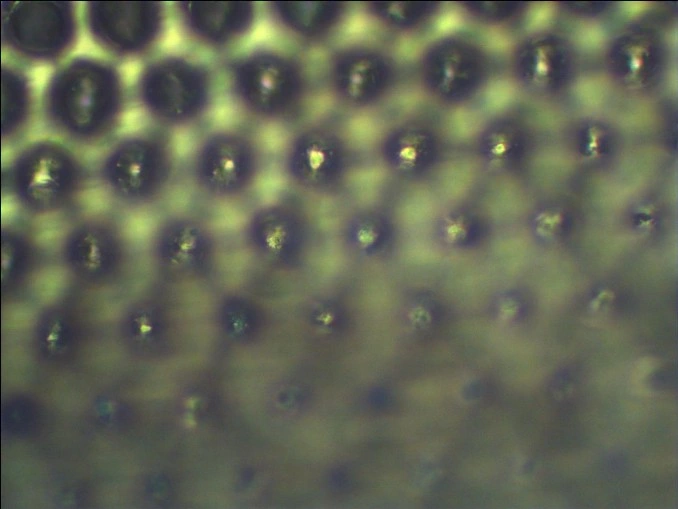

Picture of the roll before the cleaning Dr=1,3 magnification x400

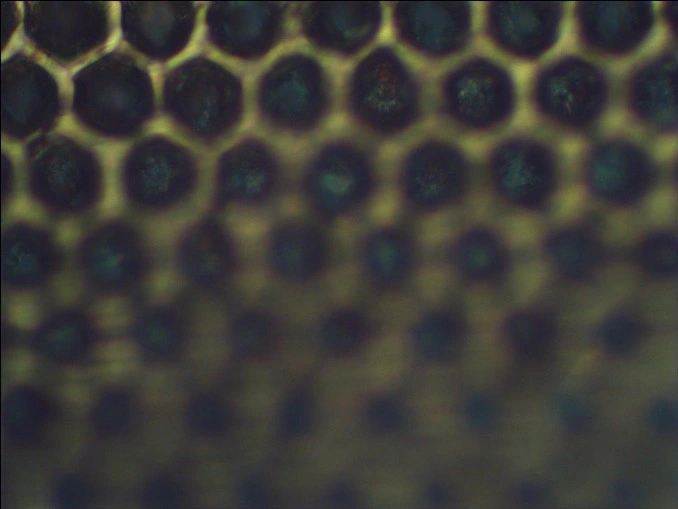

02.

Picture of the roll after the cleaning with Recyl Cobra. You can see that the chemistry gnaws the ink, however it remains in the deep and thin cells of the high line screen roll. The photo was made in the polarized light beam, the color in the cell lightens.

03.

Picture of the roll next day after the cleaning with Recyl Cobra. The cells are filled with ink. Adhesion of the new color to the old one is significantly higher than to the cleaned cells of the roll. Dr=1,42

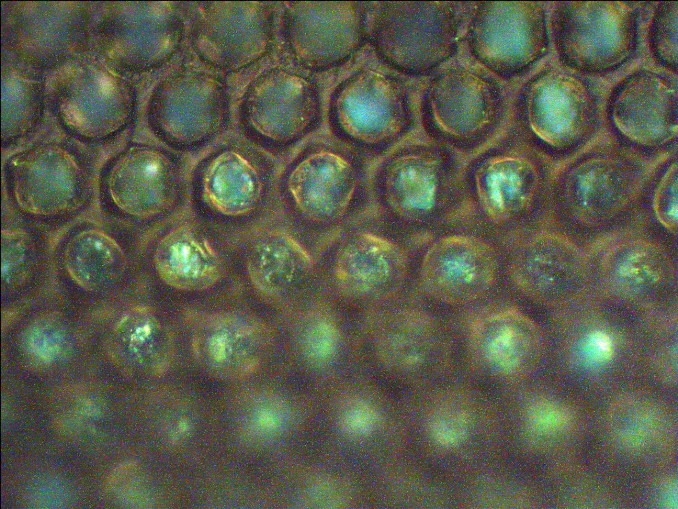

04.

Picture of the roll after safe deep cleaning LaserEcoclean. The bottoms of the cells are shining. Dr=1,63 the cleaning effect remains more than 4 months.

05.

Picture of the roll after the safe deep cleaning LaserEcoClean. You can see how the stripes are clearing up. (The picture can be magnified).

06.

The printing results before the cleaning (on the left) and after the cleaning (on the right). (The picture can be magnified).